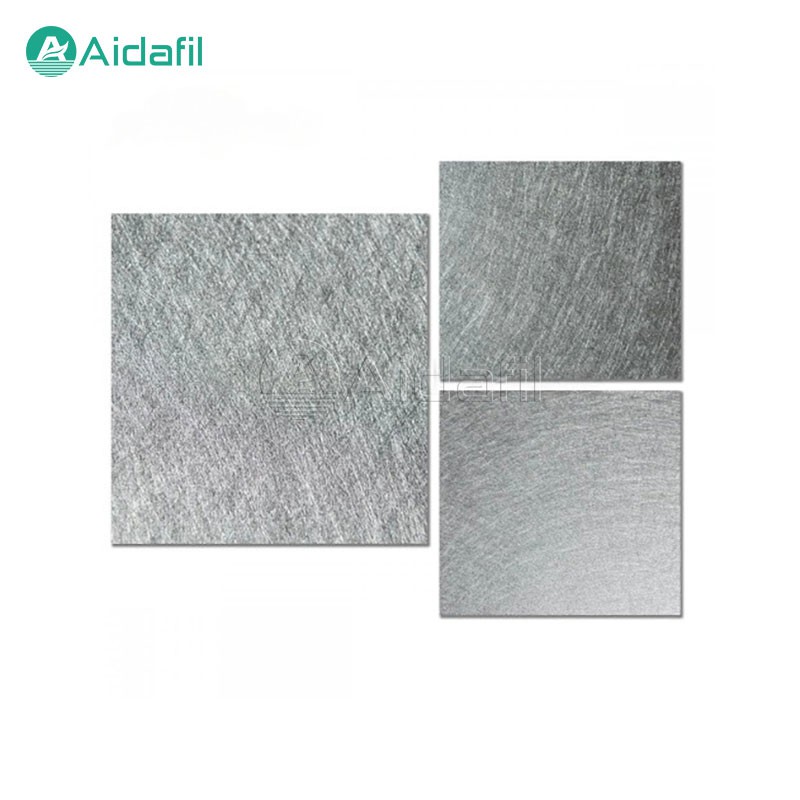

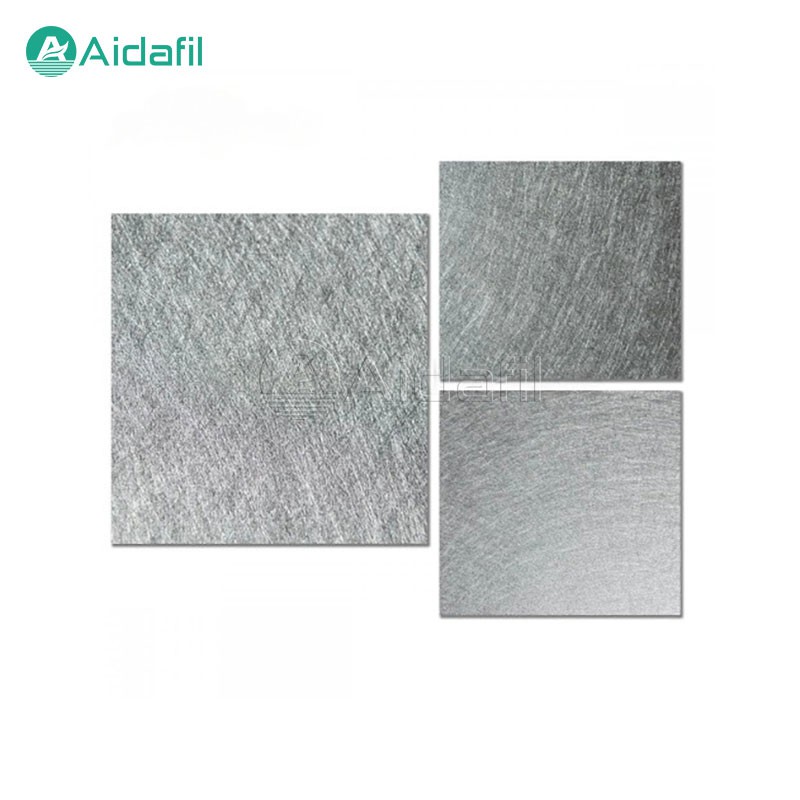

The excellent penetration rate stainless steel fiber sintered felt is an efficient filter material, mainly made of stainless steel fibers through a special process. These fibers are first laid nonwoven, then stacked and combined through a high-temperature sintering process to form a sintered felt with a unique three-dimensional network structure.

The excellent penetration rate stainless steel fiber sintered felt is an efficient filter material, mainly made of stainless steel fibers through a special process. These fibers are first laid nonwoven, then stacked and combined through a high-temperature sintering process to form a sintered felt with a unique three-dimensional network structure. This structure gives the sintered felt a high porosity, large specific surface area, and uniform pore size distribution, thus ensuring its excellent filtration performance.

1. High porosity. The high porosity of the sintered felt ensures good air permeability and a large soiling capacity.

2. Uniform pore size. By controlling the fiber diameter and sintering process, a uniform and controllable pore size distribution can be achieved, resulting in high-precision filtration.

3. High temperature resistance. Stainless steel fiber sintered felt can maintain stable performance in high temperature environments and is suitable for filtration of high temperature gases and liquids.

4. Corrosion resistance. Due to its stainless steel material, sintered felt has good corrosion resistance and can resist the erosion of a variety of chemical media.

5. Mechanical strength. The structure of the sintered felt gives it a strong mechanical strength and is stable even under severe physical shocks or vibrations.

1. Petrochemical. Used for the filtration of high-temperature, corrosive liquids in the refining process, and as a catalyst carrier.

2. Electronics industry. In the semiconductor manufacturing process, it is used for dust removal and purification of high-temperature gases.

3. Water treatment. As a pre-filtration material for ultrafilters, improve water quality and reduce the burden on subsequent treatment equipment.

4. Automotive and aviation. Used in the manufacture of fuel filtration and airbags to ensure the reliability and safety of the system.

5. Hydraulic system. As a filter element for hydraulic oil, it protects the system from particulate contaminants.

|

Air permeability (L/min, dm2, kpa) |

2) |

||||||

|

ADZB-5 |

5 |

6800 |

47 |

75 |

5 |

0.3 |

32 |

|

ADZB-7 |

7 |

5200 |

63 |

76 |

6.5 |

0.3 |

36 |

|

ADZB-10 |

10 |

3700 |

105 |

75 |

7.8 |

0.37 |

32 |

|

ADZB-15 |

15 |

2450 |

205 |

79 |

8.6 |

0.4 |

23 |

|

ADZB-20 |

20 |

1900 |

280 |

80 |

15.5 |

0.48 |

23 |

|

ADZB-25 |

25 |

1550 |

355 |

80 |

19 |

0.62 |

20 |

|

ADZB-30 |

30 |

1200 |

520 |

80 |

26 |

0.63 |

23 |

|

ADZB-40 |

40 |

950 |

670 |

78 |

29 |

0.68 |

26 |

|

ADZB-60 |

60 |

630 |

1300 |

85 |

36 |

0.62 |

28 |

|

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

1. Fiber preparation. First, stainless steel fibers are prepared by cold drawing or rapid condensation, and the fiber diameter is selected according to the filtration accuracy requirements of the final product.

2. Non-woven felt. The prepared fibers are laid into a felt shape in a certain proportion and sequence to form a preliminary fiber layer.

3. Vacuum sintering. The laid fiber felt is placed in a vacuum furnace for high temperature sintering, so that the fibers are connected through sintering points to form a stable three-dimensional network structure.

4. Post-processing. The sintered felt is cut, folded or wound as needed to make filter elements of different shapes and sizes.

1. Management Concept:

· Satisfy the customers' demand --- Touch customers, trust with our products and services

· Make employees happy --- Pursue higher material and spiritual happiness

2. Company Mission:

3. Corporate Vision:

4. Values:

· Team: Trust, responsibility, growth, win-win

Beliebte label: